Place the DuPont Corian sheet into the preheated platen press with the heat setting between 300 and 325F 150 and 165C. Thermoforming molds can be produced from a wide variety of materials depending on the size of the part quantity detail and dimensional accuracy required.

Thermoforming An Overview Sciencedirect Topics

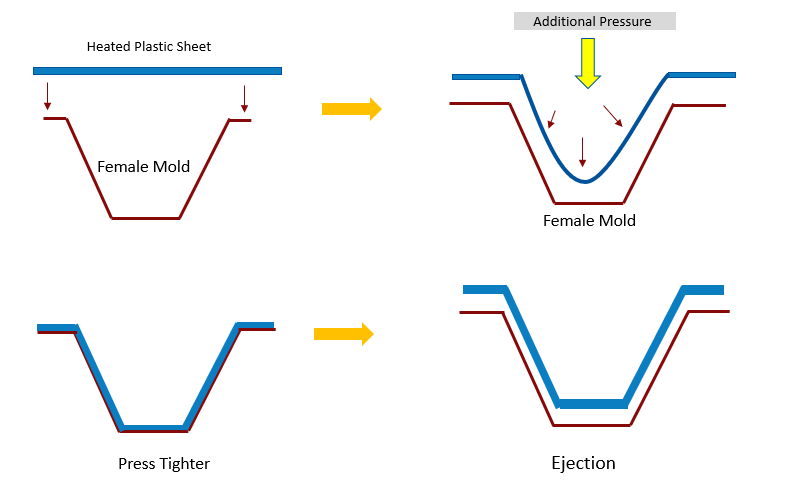

The molding is then cooled before it is ejected from the mold using reverse pressure.

. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic. Cast phenolic and epoxy resin molds work well. 508-865-8150 4 There are several different terms used to describe.

Vacuum Thermoforming Process Design Guidelines 1 Materials. Thermoforming particularly pressure forming is more cost effective for very large parts where the. Mold Design and Materials.

Proper design will account for these characteristics. Before the mold contacts the sheet a balloon of sheet is made by air which is called pre-blow Braker 2010. 1 Sheet is heated to thermoforming temperature.

4 Part removed and CNC trimmed to specification. Thermoforming is a relatively simple process to convert a flat plastic sheet into a three-dimensional object. Several experienced outside mold makers with whom we have worked for many years.

Contact Our Team Now. A rough guideline is that the sheet should be heated one minute for every millimeter so 6 mm 1. This is accomplished by shaping the sheet while it is at or above the forming temperature holding the sheet in the new configuration and removing.

PMP always say. Thin Sheet Thermoforming Mold Design Machine Controls Forming and Cooling the Parts This lesson explains the common types of molds used in thermoforming along with good and bad cooling design layouts. Thus atmospheric pressure 147 PSI sea level is.

Thermoforming is a process that involves heating a flat sheet of plastic until it is soft enough to mold. Mold is moved into a hot sheet and a vacuum is then used to remove the air trapped between the sheet and the mold. Mold cooling design cooling methods and the importance of accurate and consistent hook-ups are emphasized.

As the sheet reaches thermoforming temperature the mold comes into contact with the sheet and sheet takes the shape of the mold. In this guide we will focus on the vacuum forming and pressure forming processes. Y adding small holes through the mold and attaching a.

Design guidelines for the thermoforming process 5 5 1. For experimental or short runs wood and plaster are the most commonly used materials. Various kinds of materials have been used successfully in making molds for vacuum forming.

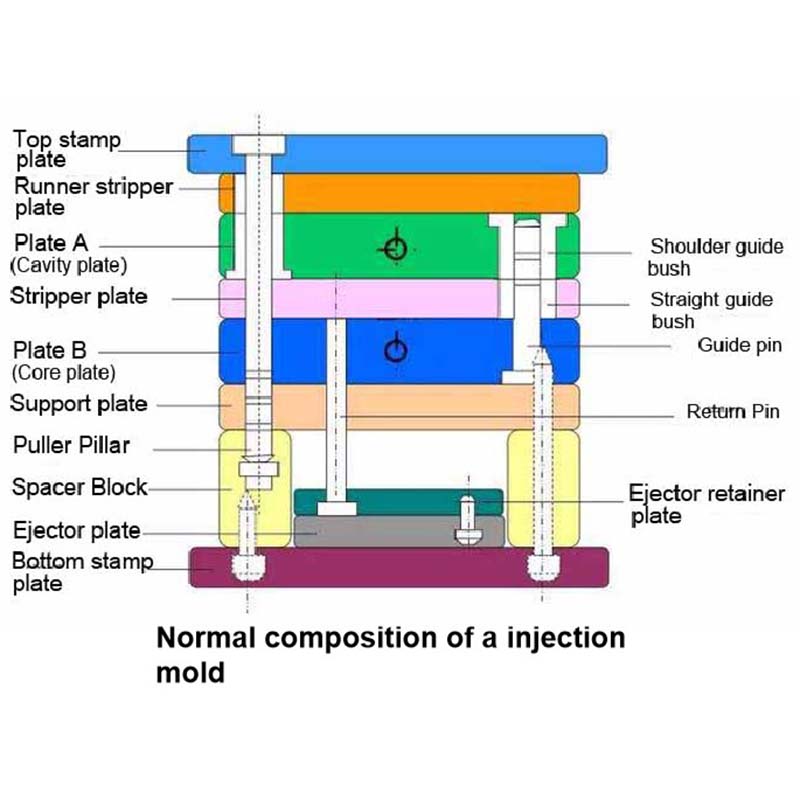

In deciding between plastic thermoforming and injection molding for your next project there are several important factors to keep in mind. The platen oven should be set to the desired sheet temperature. 14 applied topology optimization for the design of a conformal cooling layout of a thermoforming mold.

Proper design will account for these characteristics. It is important to remember that the start of the. Delivering Innovative Custom Foam Solutions For Over 25 Years.

Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. Executive Summary This report reviews the choices that may be considered for thermoforming processing. Tooling costs for thermoforming are significantly lower than tooling costs for injection molding.

Generally speaking amorphous materials like polystyrene ABS polycarbonate PVC and PVCAcrylic blends are easier to vacuum form. THERMOFORMING DESIGN GUIDELINES Revision 3-12-18 Multifab Inc. Is an industry leader in the field of vacuum and pressure formed plastics for.

3 Air is applied above the mold and vented below to form shape. Contact with the cold mold surface and the par Thermoforming is a process in which a flat thermoplastic sheet is heated and deformed into the desired shape. The sheet is pulled into the mold with a vacuum.

Thermoforming covers all processes which involve heat to shape polymers. Mold design is closely interrelated to part design and will depend on the following factors. The process is widely used in packaging of consumer products and to fabricate large items such as bathtubs contoured skylights and internal door liners for refrigerators.

Thermoforming is a broad technology genre so the report gives some background information to the various thermoforming process sub groups and links the tooling. MOLD DESIGN CONCEPT PLUG VS CAVITY The primary purpose of the mold used in the thermoforming process is to create the desired part geometry. Once it reaches the right temperature the sheet advances to the form section.

214 Cooling After molding cooling mechanism of the machine is used to cool the. Ad Flextech Specializes In Engineering Custom Foam Solutions To Suit Your Needs. 2 Heated plastic sheet is placed over the mold face covered.

In its simplest form thermoforming involves heating up a plastic sheet until it is pliable then stretching it over a mold and letting it cool so it sets to the mold shape. Design for Thermoforming Uniform thickness 10 Simpler shapes avoid under cuts etc Rounded corners 1t min 4t ideal Draft angle for removal 5 5 degree Depth of draw ratio 11 Stretch ratio 21 Shrinkage Design for holes and trim lines 30 Cost -. 4 for 6 minutes 12 mm 1.

A good design is the heart of a Mold One of the most fundamental decisions when designing a mold for the plastics thermoforming process is whether to use a plug male mold or a. PTI will default to ABS unless specified differently. 1 Thermoplastic sheet is secured heated to forming temperature.

This combination provides us control over the mold design and the capacity to meet demanding delivery schedules. 15 created a finite element-based optimization approach for. Thermoforming is the heating of a plastic sheet which is then draped over a mold while vacuum is applied.

Project 1 - This Exercise explores digitizing a hand-sketch concept and bringing it into SolidWorks and tracing around the sketch and creating a solid model.

Plastic Injection Molding Infographic Streamline Plastics Plastic Injection Plastic Injection Molding Injection Molding

Plans For Building A Table Top Hobby Vac Vacuum Forming Machine Vacuum Forming Vacuum Diy Molding

Representation Of A Thermoforming Process The Mold Object Of This Download Scientific Diagram

Download Free Vacuum Former Plans Screen Printing Machine Vacuum Hobby Kits

Dfmpro For Thermoforming Process Dfmpro Blog

China China Oem Thermoforming Mold Design Quotes Plastic Injection Molds Mestech Manufacturer And Supplier Mestech

0 comments

Post a Comment